WASTE WATER TREATMENT PIPE

A new age to clean wastewater

A new age to clean wastewater

Simple planning, fast and cost-effective construction, excellent effluent values, reliable functioning over many years and low operating costs: this is what is expected of large-scale sewage treatment plants.

With the waste water treatment pipe this becomes reality.

MBR-based sewage treatment plant. Capacity: 1000 m3/day (depending on country for approx. 10,000 people)

The WWTP technology developed by WITE is the result of many years of research and the search for solutions that are used in the field of complex plants.

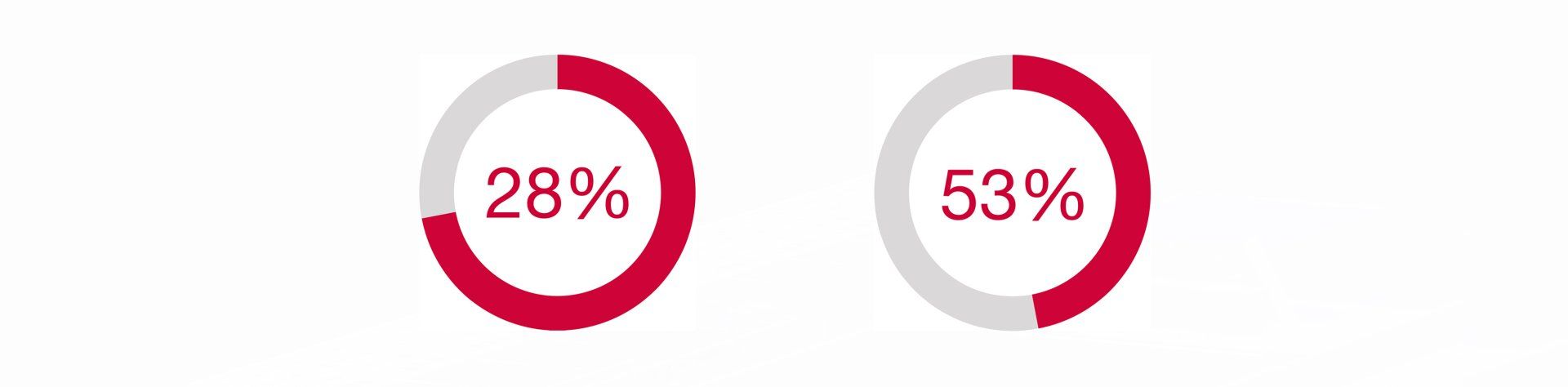

Considerable cost reduction: Basins made of GRP pipes enable costs to be reduced by up to 28% compared with similar concrete systems.

Faster construction time: When building basins with GRP pipes, a time saving of up to 53 % compared to conventional concrete basins is possible.

Faster construction time: When building basins with GRP pipes, a time saving of up to 53 % compared to conventional concrete basins is possible.

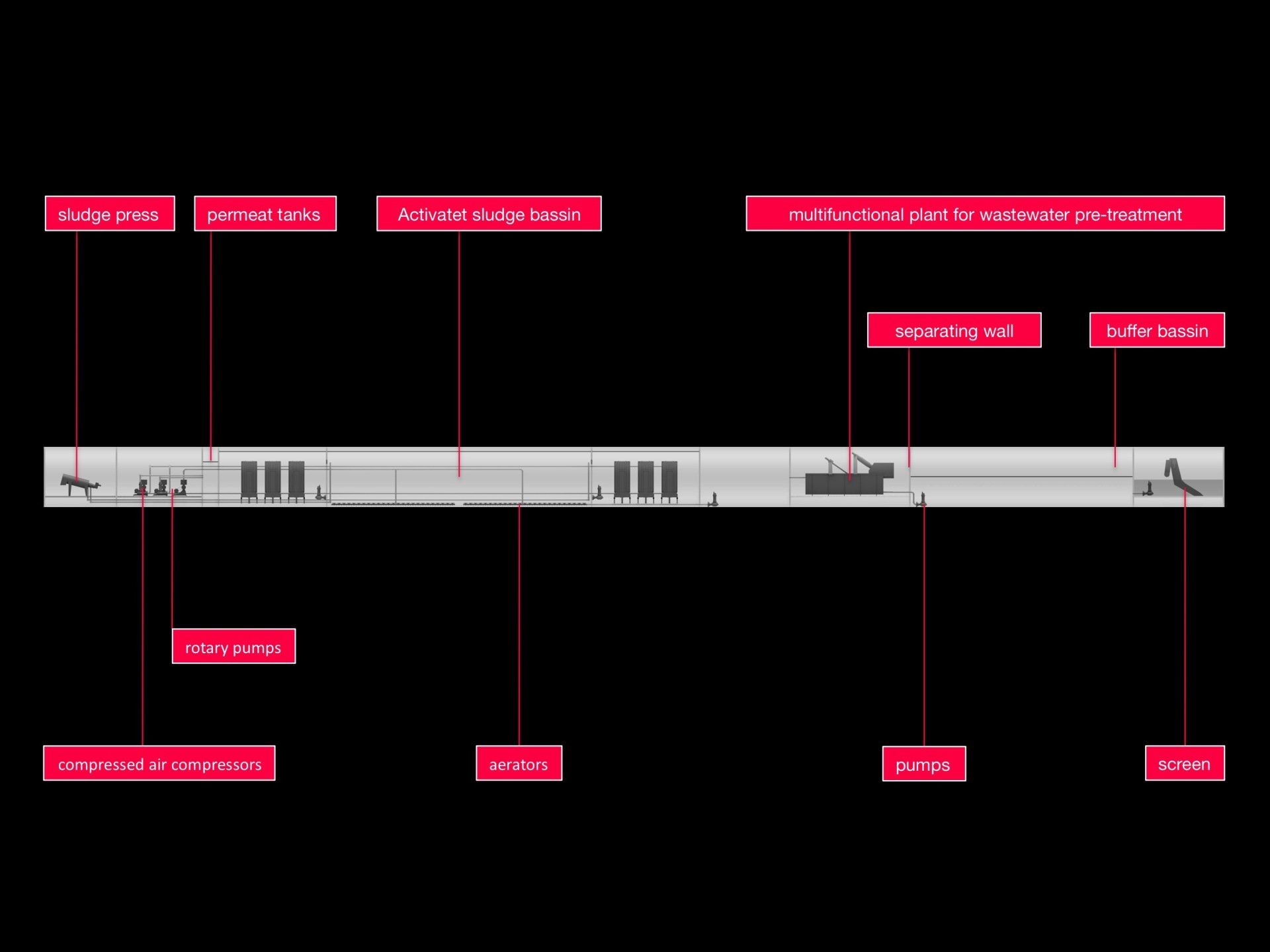

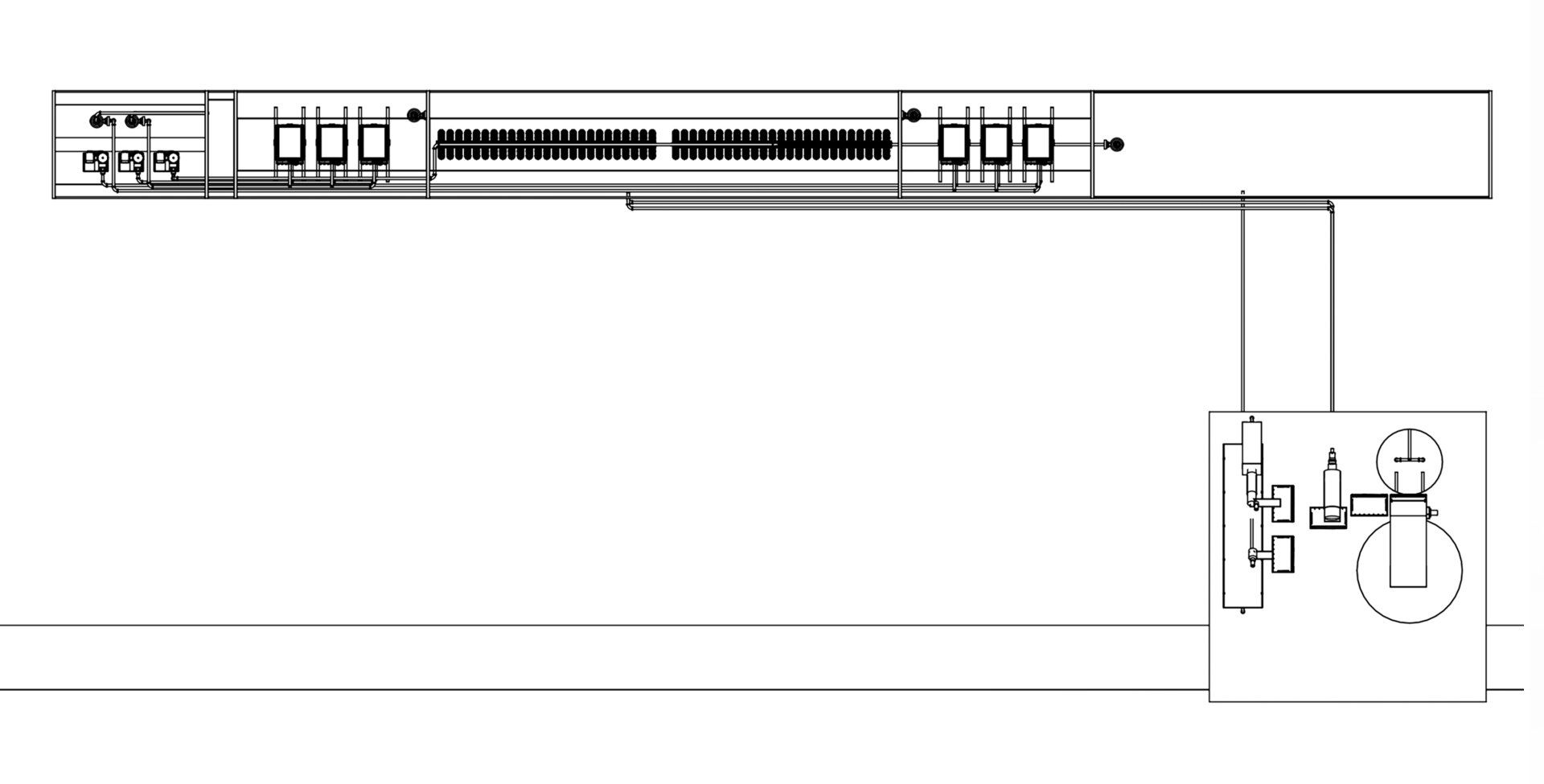

Sewage treatment plant with screening plants, sand and grease filters, aeration tanks, MBR modules, permeate tanks, sludge press, machine room, etc.

When investigating existing sewage treatment plants, we quickly noticed a decisive point: Although many plant components such as pumps, aerators, decanters, controls, etc. have been repeatedly revised over the decades and can hardly be improved, there have been practically no developments in the area of the basins - the actual shells of the sewage treatment plant processes. And this despite the fact that conventional tanks are associated with a large number of problems. This is hardly comprehensible.

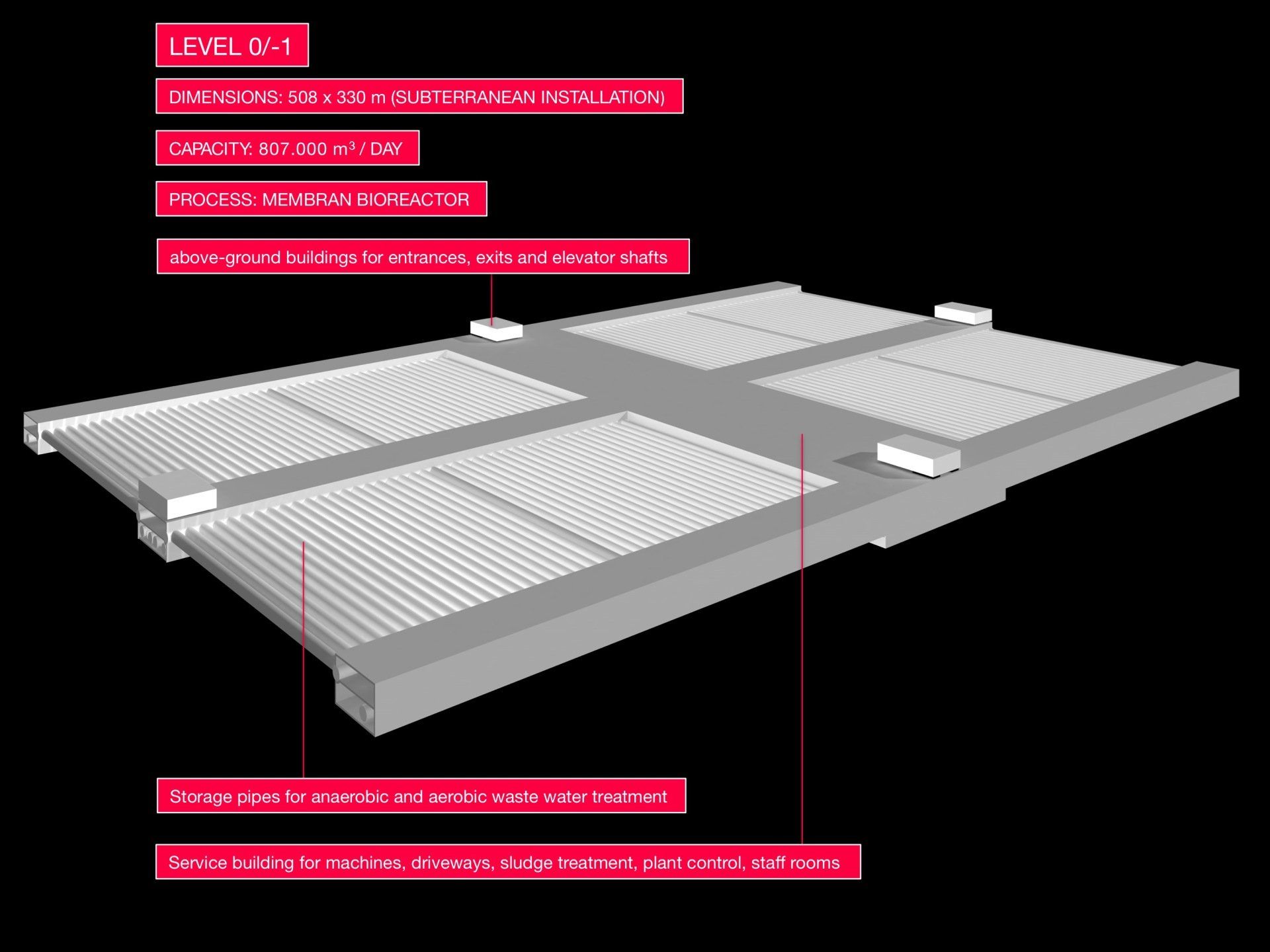

Large scale MBR-based sewage treatment plant for a daily capacity of 807,000 m3.

"In order to improve the plants exactly in this point, we are taking a radical but easy to understand step: all the tanks commonly used in sewage treatment plants are being replaced by large-format pipes with a diameter of 4000 mm"

What would trains and airplanes be without a high-tech state-of-the-art hull, what would cars be without a modern body, what would ships be without a hull that meets the latest engineering standards? In order to improve sewage treatment plants exactly in this point we take a radical but easy to understand step:

All common basins (settling and aeration basins, etc.) will be replaced by large-format pipes with a diameter of 4000 mm. These are made exclusively of glass-fibre reinforced plastic (GRP), an almost indestructible material that has been tried and tested for decades in the field of sewage technology and meets the highest quality requirements.

All common basins (settling and aeration basins, etc.) will be replaced by large-format pipes with a diameter of 4000 mm. These are made exclusively of glass-fibre reinforced plastic (GRP), an almost indestructible material that has been tried and tested for decades in the field of sewage technology and meets the highest quality requirements.

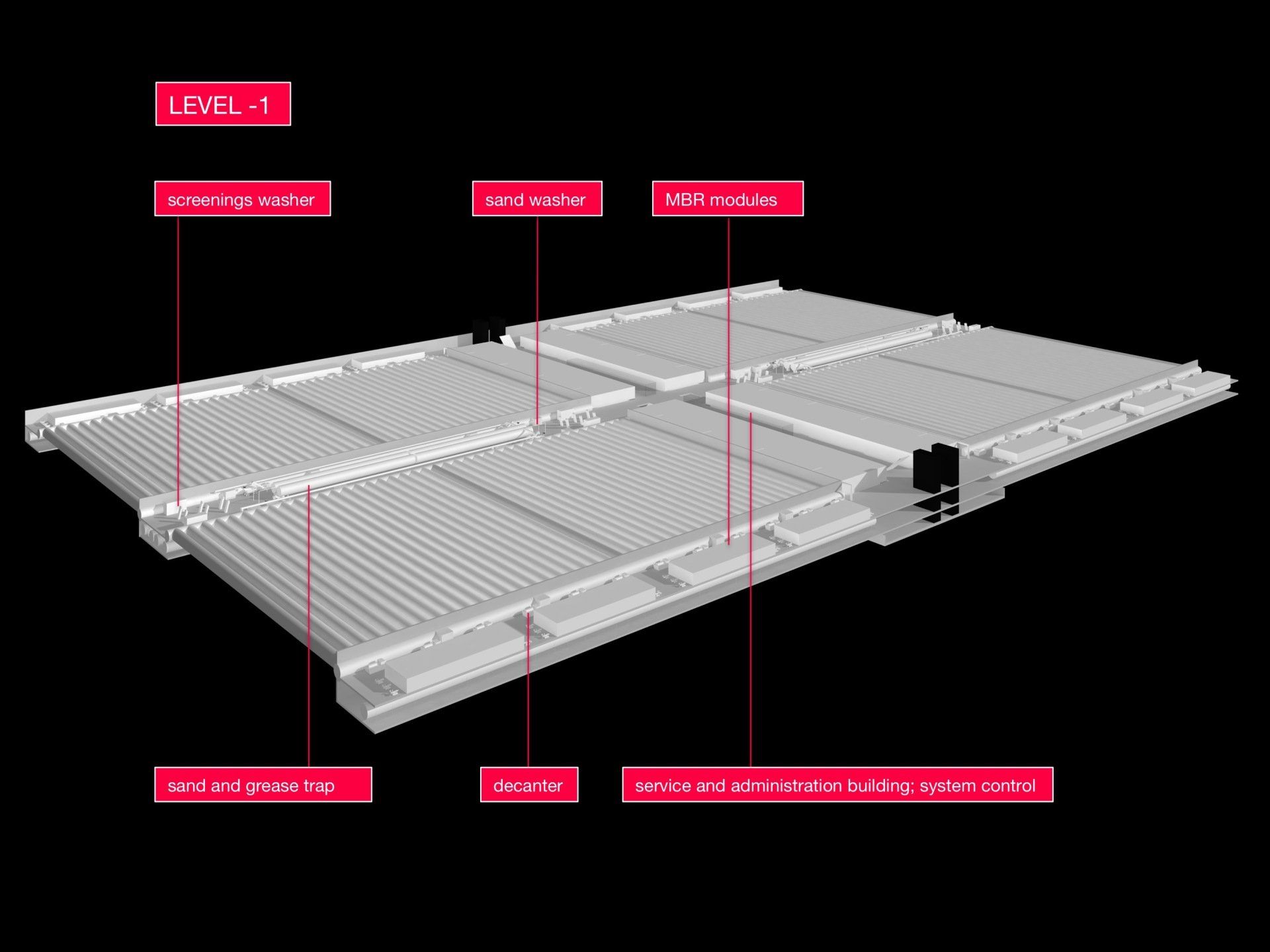

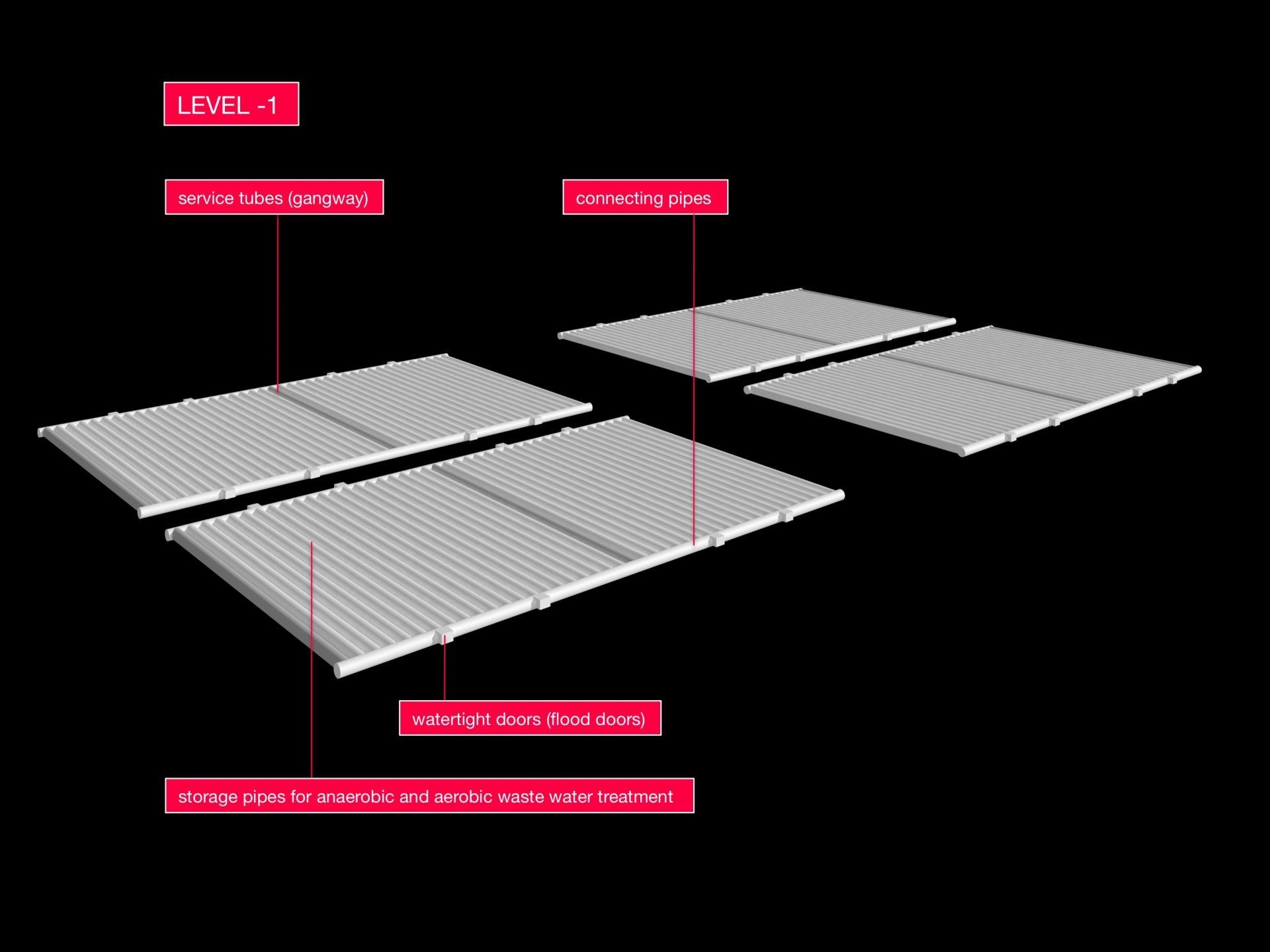

level -1 of the completely underground sewage treatment plant

We have thus succeeded in taking a development step that has probably not taken place for decades and which brings with it many advantages:

All the imponderables that have occurred so far in the planning and construction of concrete basins are eliminated. Corrosion is ruled out, the building substance can no longer be attacked by the components present in the waste water when GRP pipes are used. Concrete of inferior quality, crumbling walls, rusty reinforcing irons and constantly renewing corrosion protection layers for the preservation of the building fabric are a thing of the past.

All the imponderables that have occurred so far in the planning and construction of concrete basins are eliminated. Corrosion is ruled out, the building substance can no longer be attacked by the components present in the waste water when GRP pipes are used. Concrete of inferior quality, crumbling walls, rusty reinforcing irons and constantly renewing corrosion protection layers for the preservation of the building fabric are a thing of the past.

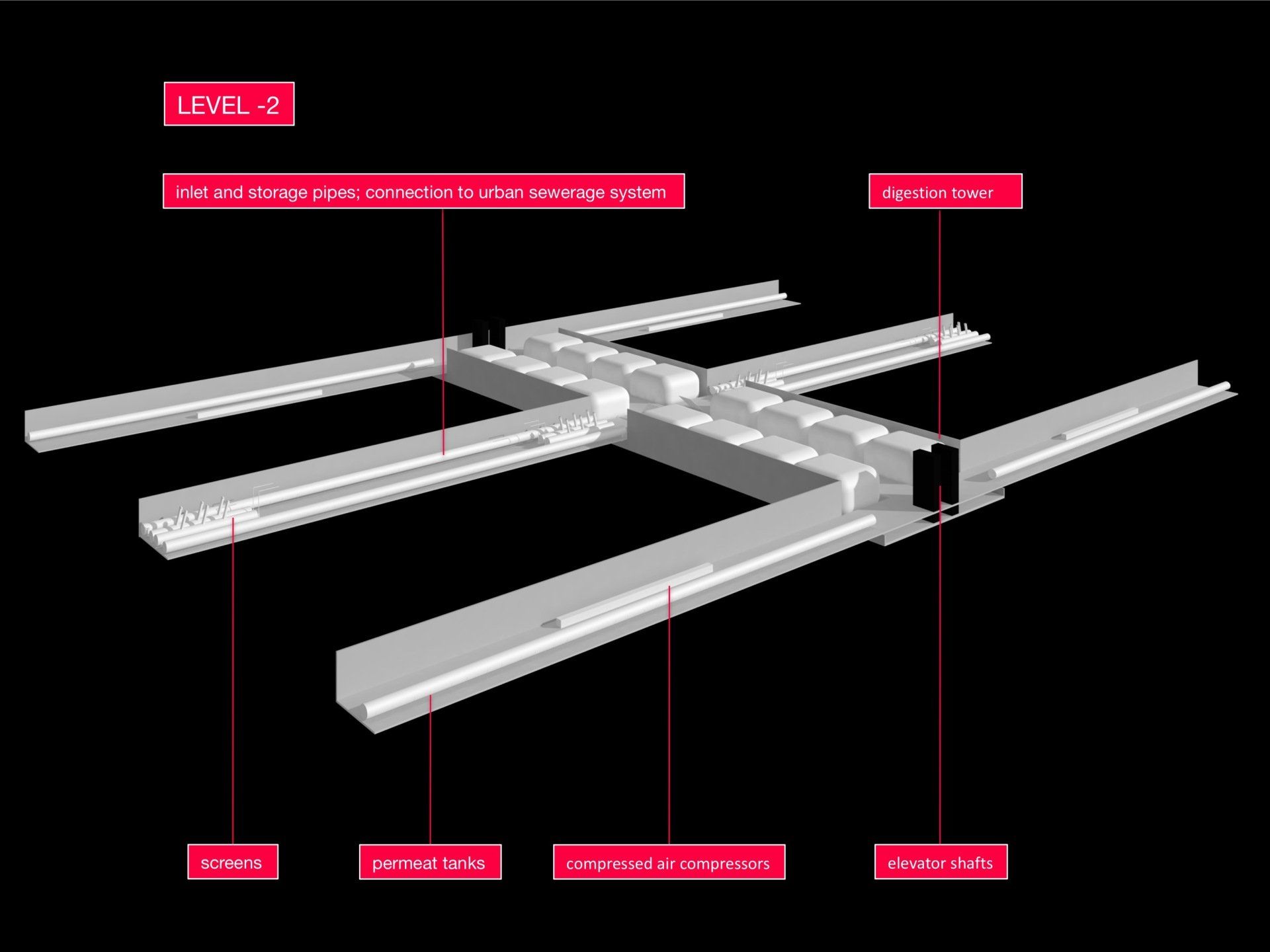

level -2 with screening plants, digestion towers and reserve tanks

"Depending on the cleaning performance requirements, the wishes of the customer, the legal regulations in the target country and the weighing of costs and benefits, the pipe system is first designed precisely for the appropriate treatment technology (e.g. ABR, MBR, MBBR, SBR)."

And that's not all: the pipes are encapsulated, odour-generating gases cannot escape and are fed to the effluent treatment in a controlled manner. The temperature inside the tanks remains more constant due to the closed design. The supply of air or oxygen for activated sludge plants can be better dosed and controlled. Measurements in closed systems are more accurate. Factors that have a positive effect on construction and operating costs.

Tanks for nitrification and denitrification

Depending on the requirements of the cleaning performance, the wishes of the customer, the legal regulations in the target country and the consideration of costs and benefits, the pipe system is designed in the first step exactly for the suitable clarification technology (e.g. ABR, MBR, MBBR, SBR).

CALCULATION AND EQUIPMENT OF THE PLANTS

The size of the pools is determined by the length of the pipe. Example calculation: A running meter with a nominal diameter of 4000 mm has a volume of 12.56 m3, 50 m running meters a volume of 628.31 m3. This corresponds to a classic circular concrete basin with a diameter of 12.46 m and a depth of 5 meters.

"The use and recombination of components that have proved their worth for decades alone has resulted in a much better system".

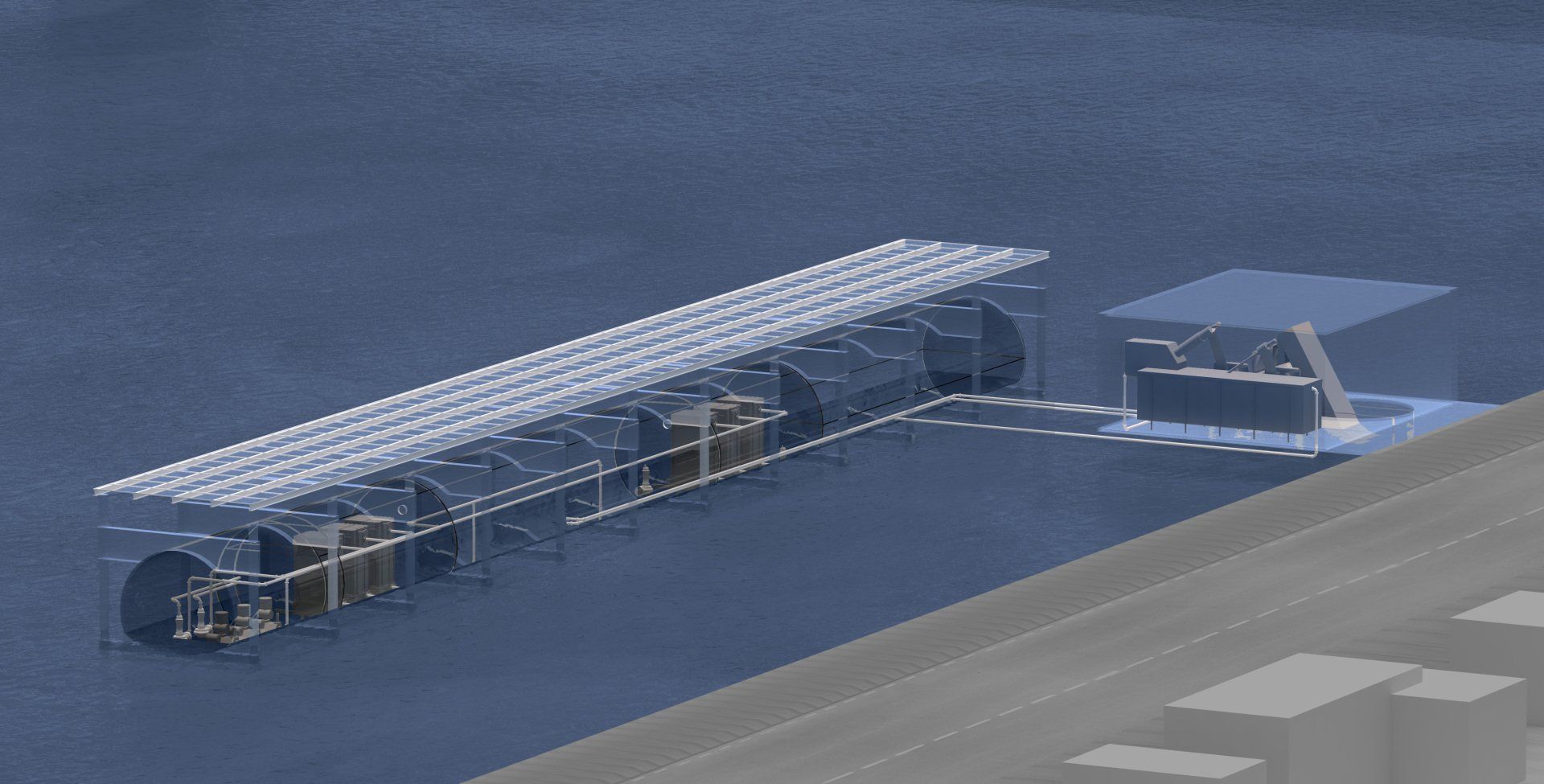

Sewage treatment plant installed in the water body

All other stations - grit and grease traps, screenings washers, MBR modules, decanters, compressed air units - can also be installed in the pipes of sewage treatment plants up to a certain size. Other important components, e.g. gratings and railings, manhole covers and manhole covers, T-beams are also made of GRP. And even the switch cabinets and control rooms are positioned in the pipes. This saves costly operating buildings.

In the next step, the GRP pipes are combined with the components required for sewage treatment plants - fittings, machines, operating platforms, manhole entrances, etc. - to form a single unit. Carefully selected components from renowned and reliable suppliers ensure that the system functions largely smoothly.

The use and recombination of components that have proven their worth for decades alone has resulted in a much better system.

In the next step, the GRP pipes are combined with the components required for sewage treatment plants - fittings, machines, operating platforms, manhole entrances, etc. - to form a single unit. Carefully selected components from renowned and reliable suppliers ensure that the system functions largely smoothly.

The use and recombination of components that have proven their worth for decades alone has resulted in a much better system.

Plan view MBR sewage treatment plant.

PRODUCTION

Since, with a few exceptions, all plant components are manufactured in cost-saving series production and in modular design completely in the factory and only the final assembly takes place at the site of operation, the projects will be implemented with a higher quality and accuracy and faster than before. This saves time and money.

"The sewage treatment plants can be installed both on land above and below ground, and smaller plants can also be installed in water."

A later expansion is also easy to practice by adding new pipe units. If there is no space, the pipe strings can even be positioned on top of each other.

INSTALLATION

The sewage treatment plants can be installed both on land above and below ground, smaller plants can also be installed in water bodies.

WITE SEWAGE TREATMENT PLANT SIZES

With a capacity of 500 m3 up to 1,000,000 m3 per day, plants of any size can be implemented.

CO2 EMISSIONS

Although the CO2 emission of 1.35 t from the production of GRP pipes is higher than that of concrete (0.26 t), the emission is put into perspective in a direct comparison of structures, as GRP storage basins require considerably thinner walls for the same static loads. If a concrete basin requires a wall thickness of 40 cm for the side walls or 50 cm for the base plate, the same stor-age chamber can be used with a GRP pipe with a maximum wall thickness of 5.6 cm. If, for ex-ample, 2 basins with a volume of 400 m3 capacity are compared, in which one was built from GRP and one from concrete, a CO2 emission of 72.95 t results for the concrete basin and a CO2 emission of 49.01 t for the GRP basin. GRP is therefore not only an excellent structural alternative, the high-tech building material also makes an outstanding contribution to environmental protection.

CO2 emissions: With the same basin sizes, CO2 emissions can be reduced by 30% or more compared to con-crete basins by using GRP pipes.

Concrete

At WITE, concrete is only used in large sewage treatment plants for service buildings, i.e. plant components that do not come into contact with waste water.