STORM WATER BASINS

Sealed inner cities, undersized sewer systems, massive increase of rainfalls due to climate change: Storm water management is at the top of the agenda of engineers and urban planners.

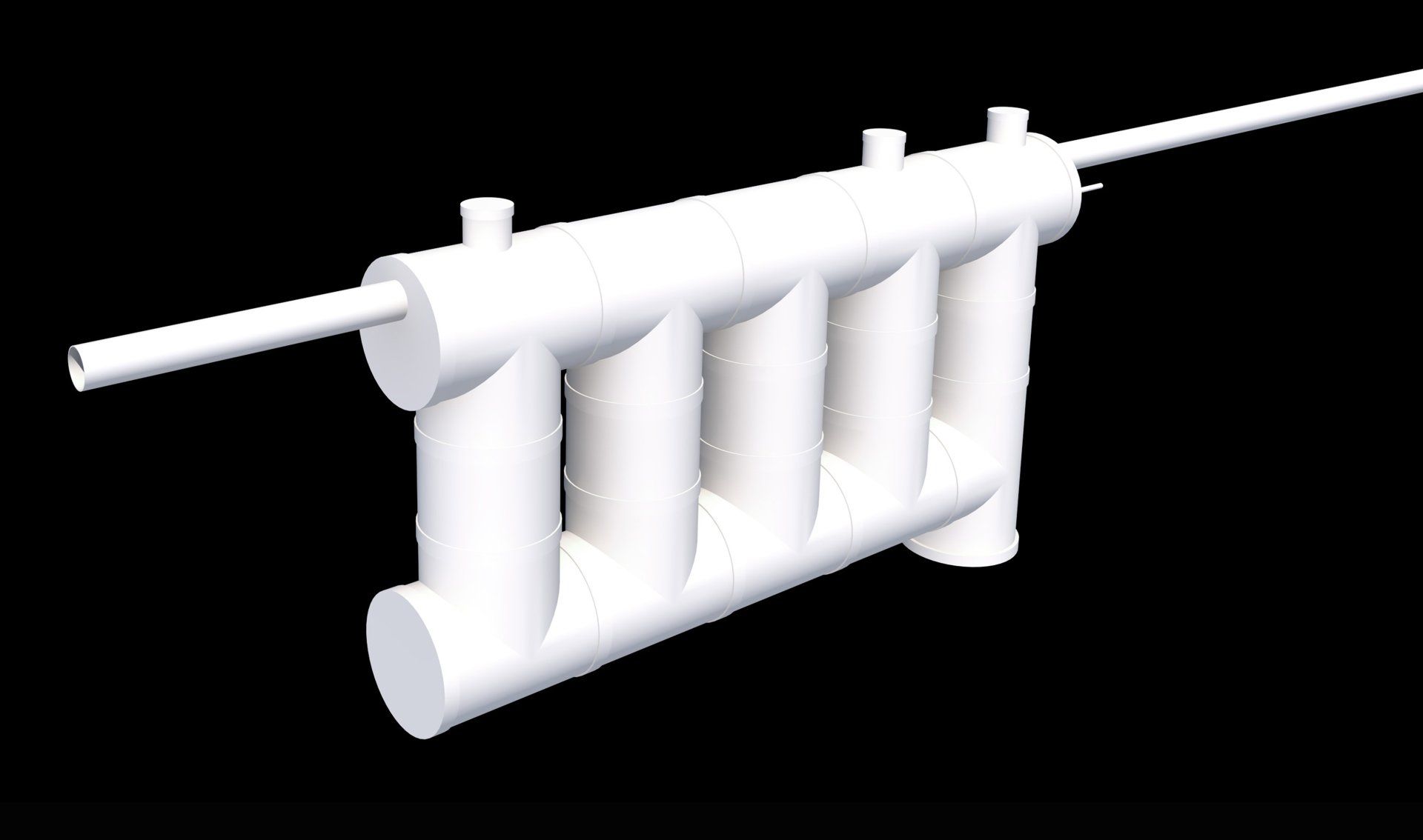

Lying basin for underground installation.

THE COMPONENT SYSTEM

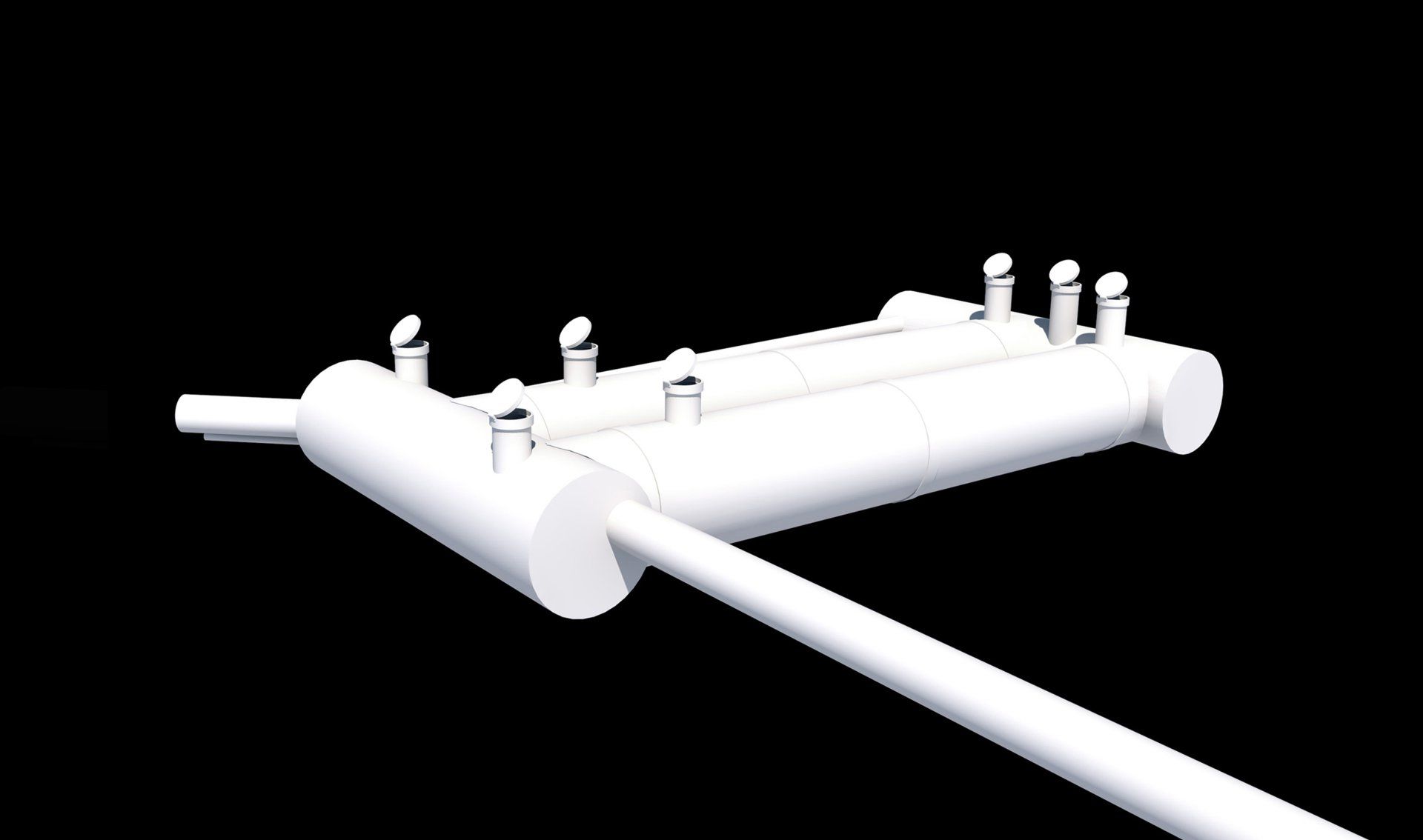

In the area of storm water basins, WITE can offer a uniquely flexible, quickly implementable and cost-effective system: A component system made of GRP pipes that is variable in size with volumes from 100 to 50,000 m3 and can be installed horizontally, vertically, underground, above ground and also in the water. This means that the basins can be adapted to any location.

"The plant components are manufactured in the factory with high precision in the millimeter range, pre-assembled and connected on site only with large-format couplings."

Basin with a volume of approx. 450 m3 for underground installation.

The plant components are manufactured in the factory with high precision in the millimeter range, pre-assembled and connected finally on site with large-format couplings. The assembly takes approx. 4 hours per component, a basin with a volume of 1000 m3 can be assembled from approx. 18 components in two weeks.

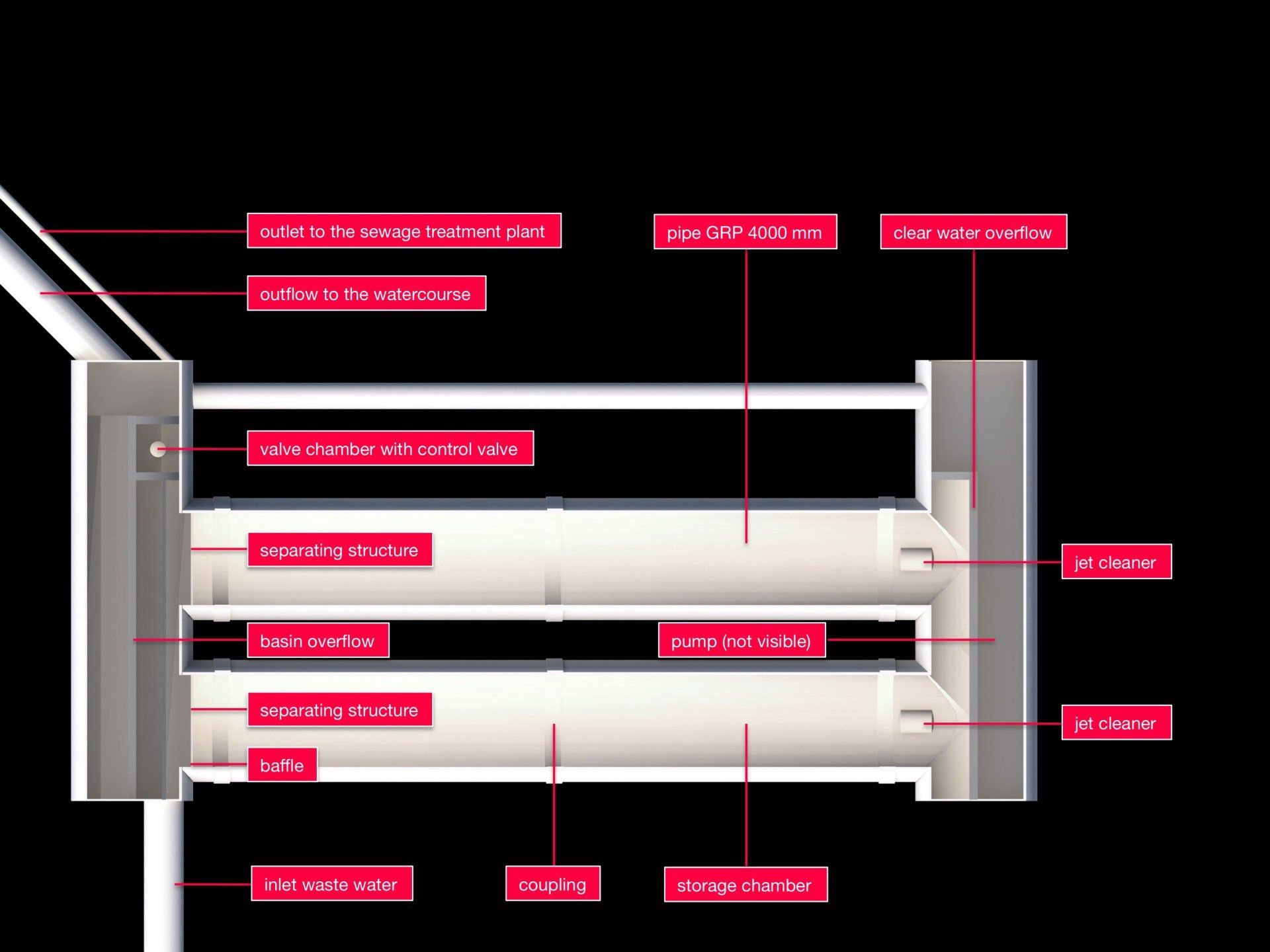

List of the essential components of the storm water basin.

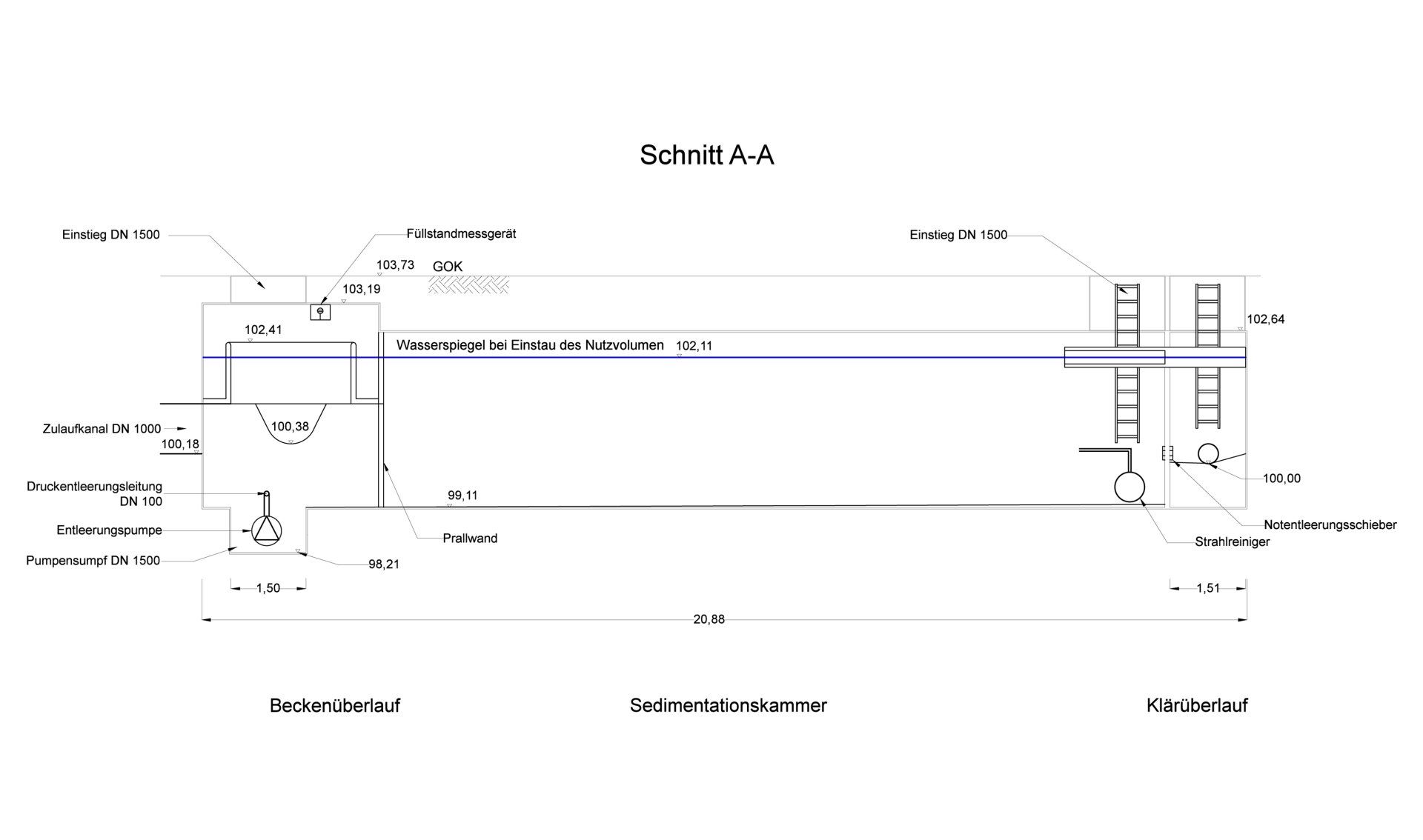

Even large basins, including all ground work, can be moved quickly and the construction time can be reduced by 50-70% compared to concrete basins. Especially in inner-city areas, this leads to a reduction of the load on traffic and the economy to a minimum. In addition to the actual storage chamber made of large-format GRP pipes from 1600 mm to 4000 mm, other large components such as the basin overflow, the clarification overflow and the separation structure are made of GRP using laminates.

Costs: Significant cost reduction. Structures made of GRP pipes enable costs to be reduced by up to 28% compared with similar concrete plants.

Construction time: Faster construction time. When implementing plants with GRP pipes, e.g. rain overflow basins, time savings of up to 53 % compared to conventional concrete basins are possible.

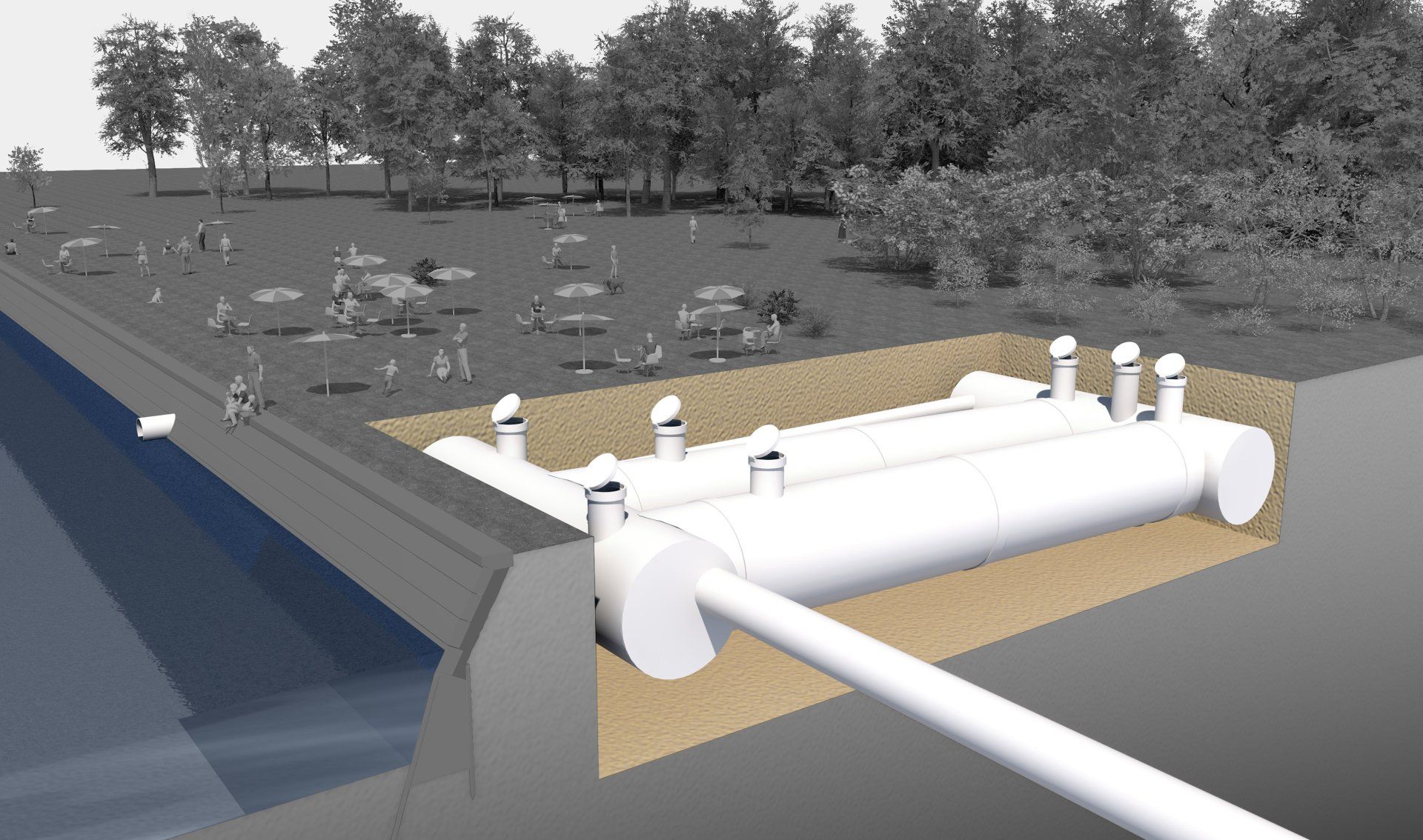

Storm water basins for mixed water installed in the water body in Berlin.

The avoidance of many different materials - as is standard with conventional plants - facilitates technical planning, lowers costs, increases quality and extends lifespan.

"When developing the WITE storm water basins, we were able to draw on the experience of 24,000 basins implemented in Germany since 1970."

Even if the technology of storm water basins may seem simple, a high level of technical understanding is required for planning. When developing the WITE storm water basins, we were able to draw on the experience of 24,000 basins that have been built in Germany since 1970. In no other country worldwide this technology is so advanced. And yet, thanks to intensive research - carried out with renowned institutions and universities - we have once again succeeded in achieving major further developments in terms of technology and economic operation.

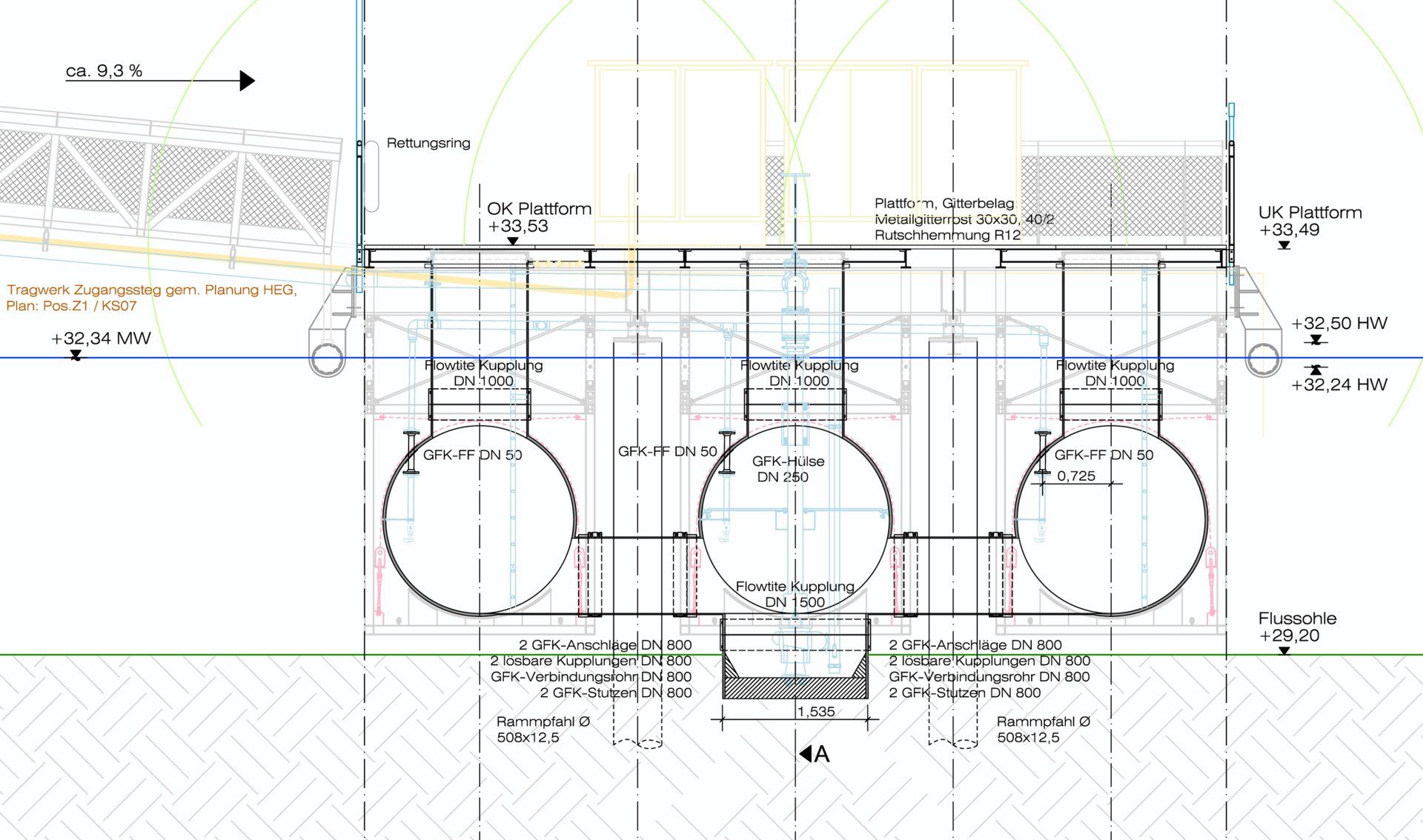

Detailed plan of cut.

"Above all, it is a groundbreaking technical innovation that improves the function and lifespan of the basins: the construction of the basins from glass fiber pipes that have been tried and tested for decades."

LATEST RESEARCH LEADS TO A SUBSTANTIAL IMPROVEMENT OF THE EQUIPMENT

Above all, it is a groundbreaking technical innovation that improves the function and lifespan of the basins: the construction of the basins from glass fiber pipes that have been tried and tested for decades.

The improvements result in implementation of corrosion-free plants in which concrete is completely abandoned. This means that many unnecessary steps are no longer necessary in the design and construction of the storage facility: Concrete formwork and reinforcement steel are redundant, the statics are considerably simplified, long drying phases are a thing of the past, as are nasty surprises caused by poor quality concrete.

Switch cabinet with connection to the control center.

In conventional basins, corrosion occurs particularly in the area of pump stations, expansion joints and ducts and can damage systems up to complete destruction. The worldwide damages in the field of urban water management is known and burdens the national economies with billions, which could have been avoided by the use of alternative materials - for example plastics: As can be seen from 40 years of operational experience, GRP pipes are not affected by corrosion.

Exhaust air treatment.

FURTHER WASTE WATER TREATMENT IN THE BASIN

In order to increase the effectiveness of basins with full filling and the connected overflows, they can be equipped with screening plants or lamella separators, for example. With the latter a particle retention of up to 60% can be achieved.

Vertical GRP storage basin with lamella clarifiers for further wastewater treatment.

FOUNDATION

There are several tried and tested methods to counter buoyancy at high groundwater levels. The guideline value of pipe diameter x 0.75 height of the superimposed load applies for a cover and the associated superimposed load. Furthermore, geotextile can be used, the pipes are mounted on an in-situ concrete floor slab or embedded in liquid soil.

Upright installed storm water basin, e.g. for waste water storage under roads.

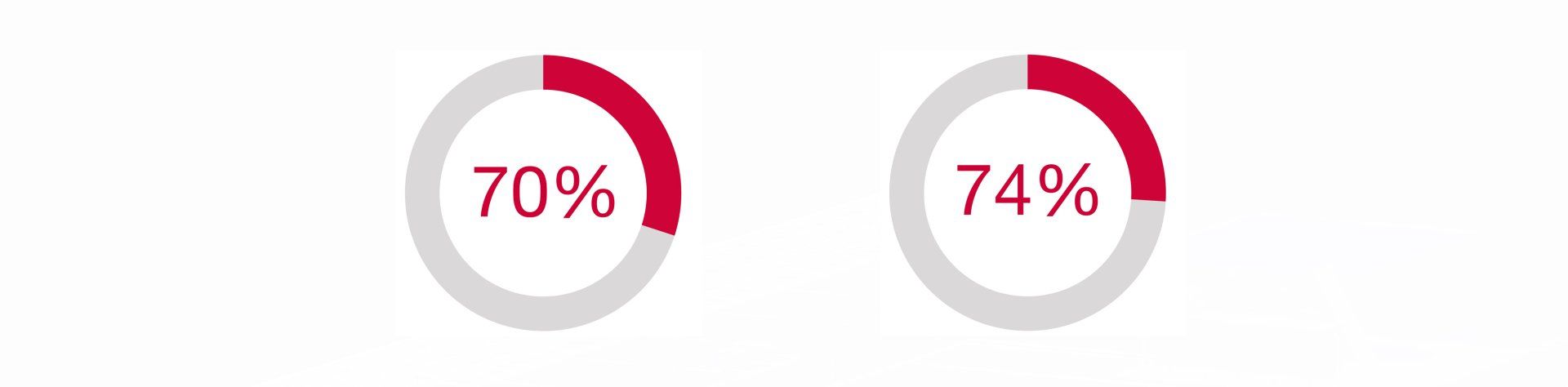

Weight: Reduced weight. Due to the up to 70 % lower weight compared to concrete pipes, even large pipe lengths and diameters can be moved with the excavator. If necessary, the building of construction roads can be avoided.

Wall roughness: The surface of GRP pipes is up to 74% smoother than that of concrete pipes. This reduces adhesion and deposits in the pipe and thus the operating costs.

Wall roughness: The surface of GRP pipes is up to 74% smoother than that of concrete pipes. This reduces adhesion and deposits in the pipe and thus the operating costs.

OPERATION

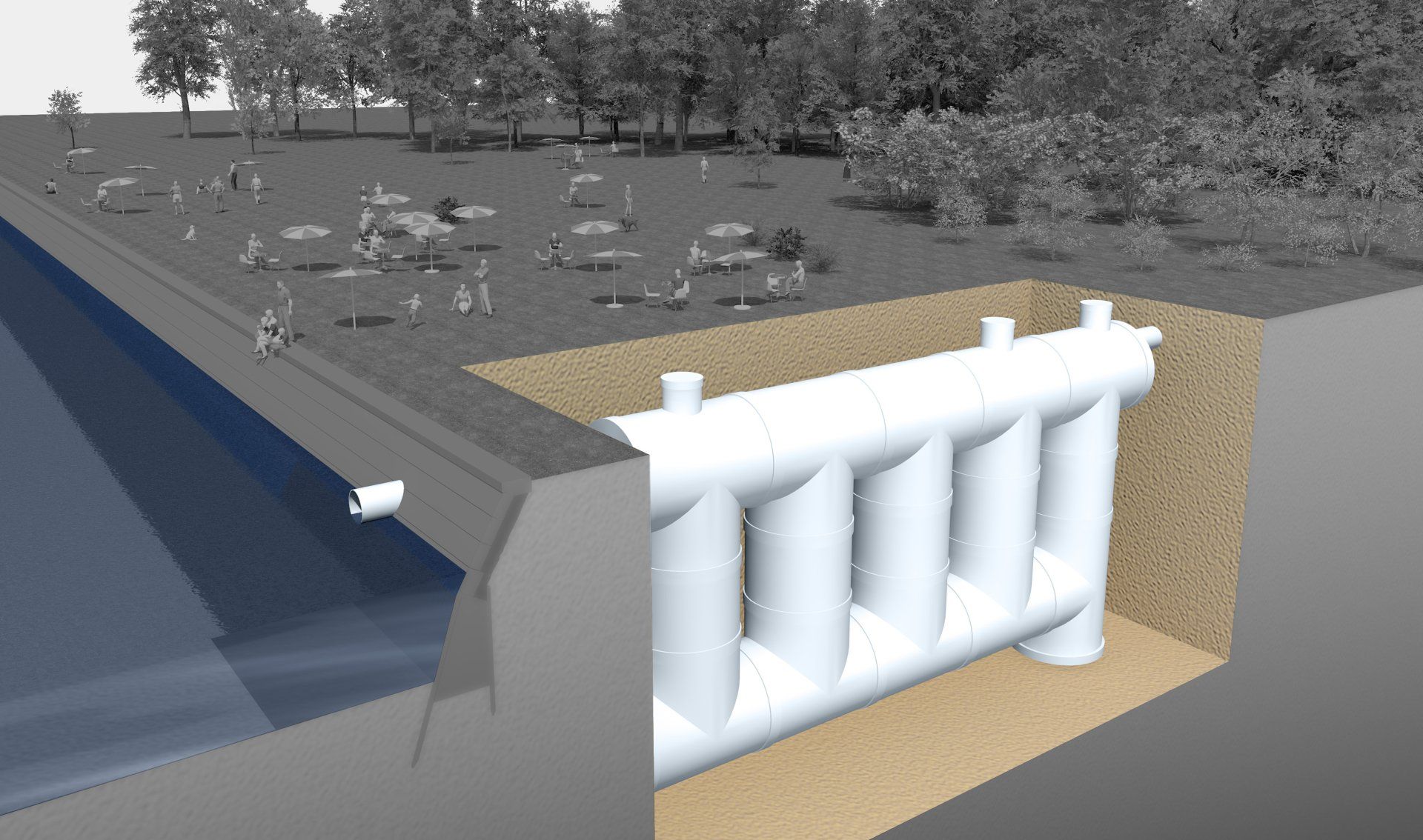

In addition to the main tasks of waste water storage and sedimentation, which are to be fulfilled by the basin, the operator also seeks great importance in a sedimentation-free and thus cost-reducing operation. Naturally, the shallower, larger and more planar the sedimentation area, the better the sedimentation will find a foothold.

Storm water basin under a public park.

The unfavorable geometry of conventional "shoe box" plants and cleaning systems, that are not designed for the basins, result in manual cleaning intervals. They have to be carried out every half to one year, sometimes however 10, 20 or up to 30 times a year by the operating personnel and cause high operating costs. This can be avoided with today's technology and planning.

Horizontal GRP storage basin.

"Therefore, the ideal system consists of GRP pipes, thus an excellent basin geometry and jets to prevent deposits."

In this case, the pipe is an advantage over the rectangular basin body, as the floor area is reduced by the immediately rising side walls. In addition, the GRP pipes have a low wall roughness, which is 70-90 % less than concrete and therefore offers less contact surface for adhesions. The cleverly programmed jets designed for pipes minimize deposits once again, so that manual cleaning is only required every 4-6 years. Therefore, the ideal system consists of GRP pipes and thus an excellent basin geometry and jets to prevent deposits.

COSTS AND CONSTRUCTION TIME

In terms of costs, savings of 10-28% - compared to costs of conventional plants - can be assumed in most cases. The construction time reduces up to 53%.

CO2 emissions

Although the CO2 emission of 1.35 t from the production of GRP pipes is higher than that of concrete (0.26 t), the emission is put into perspective in a direct comparison of buildings, as GRP storage basins require considerably lower wall thicknesses for the same static loads. If a concrete basin requires a wall thickness of 40 cm for the side walls or 50 cm for the base plate, the same storage chamber can be used with a GRP pipe with a maximum wall thickness of 5.6 cm. If, for example, 2 tanks with a volume of 400 m3 capacity are compared, where one was built from GRP and one from concrete, the result for the concrete basin is a CO2 emission of 72.95 t, and for the GRP tank a CO2 emission of 49.01 t. GRP is therefore not only an excellent structural alternative, the high-tech building material also makes an outstanding contribution to environmental protection.

Although the CO2 emission of 1.35 t from the production of GRP pipes is higher than that of concrete (0.26 t), the emission is put into perspective in a direct comparison of buildings, as GRP storage basins require considerably lower wall thicknesses for the same static loads. If a concrete basin requires a wall thickness of 40 cm for the side walls or 50 cm for the base plate, the same storage chamber can be used with a GRP pipe with a maximum wall thickness of 5.6 cm. If, for example, 2 tanks with a volume of 400 m3 capacity are compared, where one was built from GRP and one from concrete, the result for the concrete basin is a CO2 emission of 72.95 t, and for the GRP tank a CO2 emission of 49.01 t. GRP is therefore not only an excellent structural alternative, the high-tech building material also makes an outstanding contribution to environmental protection.

CO2: With the same basin sizes, CO2 emissions can be reduced by 30% or more compared to concrete basins by using GRP pipes.

EXAMPLES OF GRP MANUFACTURERS

https://www.youtube.com/watch?v=qH31XvJGAUc

EXAMPLE OF A JET

https://www.youtube.com/watch?v=_pFkzpisHAo

https://www.youtube.com/watch?v=udGJN3Yo-lc

https://www.youtube.com/watch?v=qH31XvJGAUc

EXAMPLE OF A JET

https://www.youtube.com/watch?v=_pFkzpisHAo